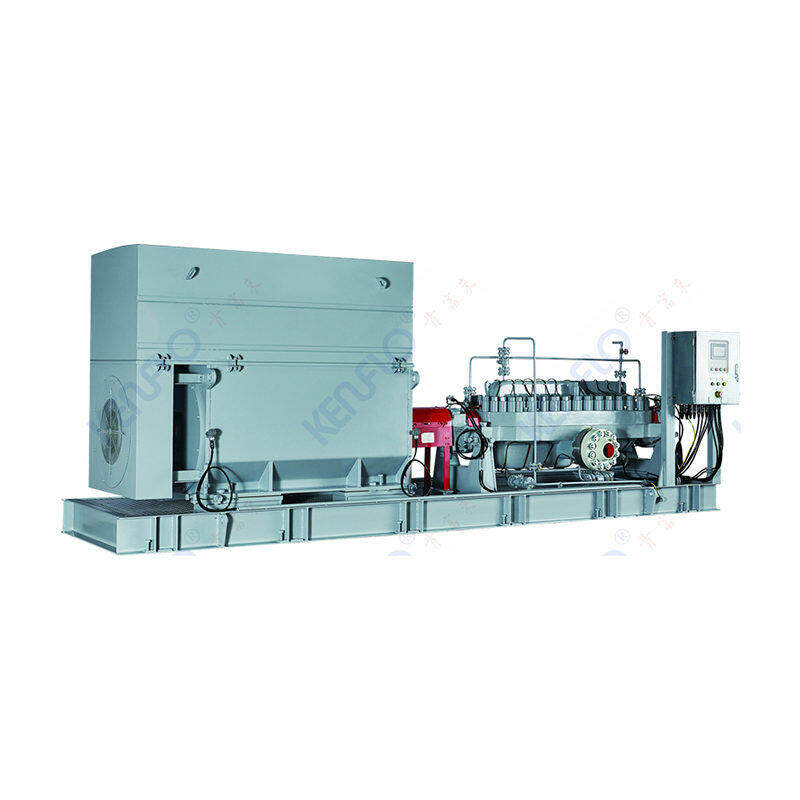

KHP Horizontal Axially Split Casing Multistage Pumps

Based on independent research and development, Kenflo has been winning the market by continuously launching products with advanced technology, high efficiency and energy saving and reliable operation. After years of effort, the centrifugal pumps have been upgraded, new series of end suction pump, inline pump and API pump have been developed,and widely applied in large petrochemical site and the energy conservation transformation projects.

Conforms to API 610 BB3 construction. High efficiency and energy saving, durable and convenient maintenance. It is used for high-pressure long-distance transportation of crude oil, high-pressure water injection (replacement for imported brands), seawater desalination, coal industry, refinery and coking units and other industries.

1、 Product introduction

KHP pump is a horizontal split multistage centrifugal pump newly developed by our company. It is a new generation of high-pressure multistage pump products developed by using hydrodynamic calculation method CFD computer-aided design method on the basis of selecting hydraulic model.

2、 Product features

1. It has the advantages of high efficiency and energy saving, firmness and durability, convenient maintenance and so on.

2. The pump shell is divided axially. The suction and discharge ports are below the pump axis and perpendicular to the axis, which is convenient for installation and maintenance.

3. The double vortex chamber design can balance the hydraulic radial force and prolong the service life of bearings and mechanical seals.

4. High efficiency, excellent hydraulic model and compact runner design are adopted.

5. The impeller is arranged symmetrically, which can realize the balance of axial force for a long time.

6. For high balance requirements, the impeller shall be subject to static balance inspection, and the rotor components shall be subject to high dynamic balance inspection.

7. The first stage impeller has good cavitation resistance.

8. Reliable bearing. The pump bearing adopts SKF brand bearing combination, which can better balance the stress of the rotor.

9. Installed near the center line, it can transport liquids with high temperature.

10. The heavy-duty bolt can effectively prevent the deformation of the pump shell and interstage leakage.

11. It is convenient to control. The bearing body is equipped with monitoring interface of vibration and temperature measuring device, which can be monitored online.

12. High configuration, reasonable material matching + all stainless steel rotor parts, equipped with container metal bellows mechanical seal, self flushing mechanism with rotary liquid separator, no external sealing liquid system is required, and the service life is long.

13. This series has 23 specifications and models, which can provide a variety of performances with different impeller diameters and different stages for selection.

14. API 610 bb3 pump type, and the product standard is API 610 (GB / T 3215).

3、 Technical parameters

Pump diameter: suction 150 ~ 200mm, discharge 80 ~ 150mm

Lift: 1740m

Flow: 280m³/ h

Medium temperature: – 15 ℃ ~ + 104 ℃

4、 Model representation

For example, khp230-115×12: KHP is the series code of horizontal split multistage pump centrifugal pump, 230 is the design point, the nominal flow is 230m3 / h, 115 is the nominal head of single stage pump 115m, and 12 is the pump type with 12 impellers.

5、 Application field

KHP horizontal split multistage pump can be used for high-pressure transportation of crude oil and high-pressure water injection in oil field, as well as long-distance and high-pressure transportation of clean water or liquid with physical and chemical properties similar to water. The high temperature of the transported liquid does not exceed 104 ℃, which is widely used in industries requiring high pressure, such as oil field, petrochemical, steel, mining, power generation, port and so on.